Fixing My Dad’s Grill

Why:

When a key piece on my dad’s grill broke, he was dissapionted at how few and poor qualtiy the options for replacments were. So I decided to see if I could do better.

How:

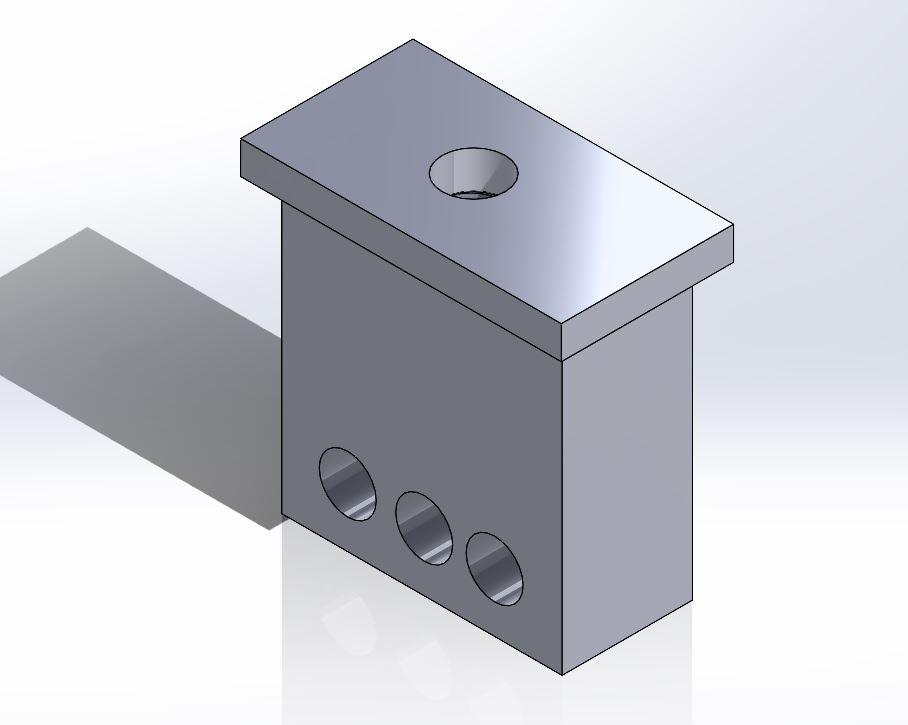

I took the broken part and reconstructed it in SolidWorks. Then printed a protoype to check fit. Once everything fit perfect, I printed the first official piece. It did not last too long however, so I continued to reprint with different infills and densities to find the most durable combination.

Results:

Currently the part sits with a honeycommb pattern and close to 50% infill. It has lasted through the summer and still looks good.

The part was made with PLA filament, which generally doesn’t stay strong for very long under sun and humid conditions. So if the part breaks again, I may reprint with 100% infill, or explore different materials I did not have on hand.