Testing Strength vs. Geometry of 3D Printed Drone Arms

After proposing my project subject, I decided on the three factors and two levels for each. This made the expirement a 2^3 factorial design.

- Cross sectional geometry

- Material

- Wall thickness

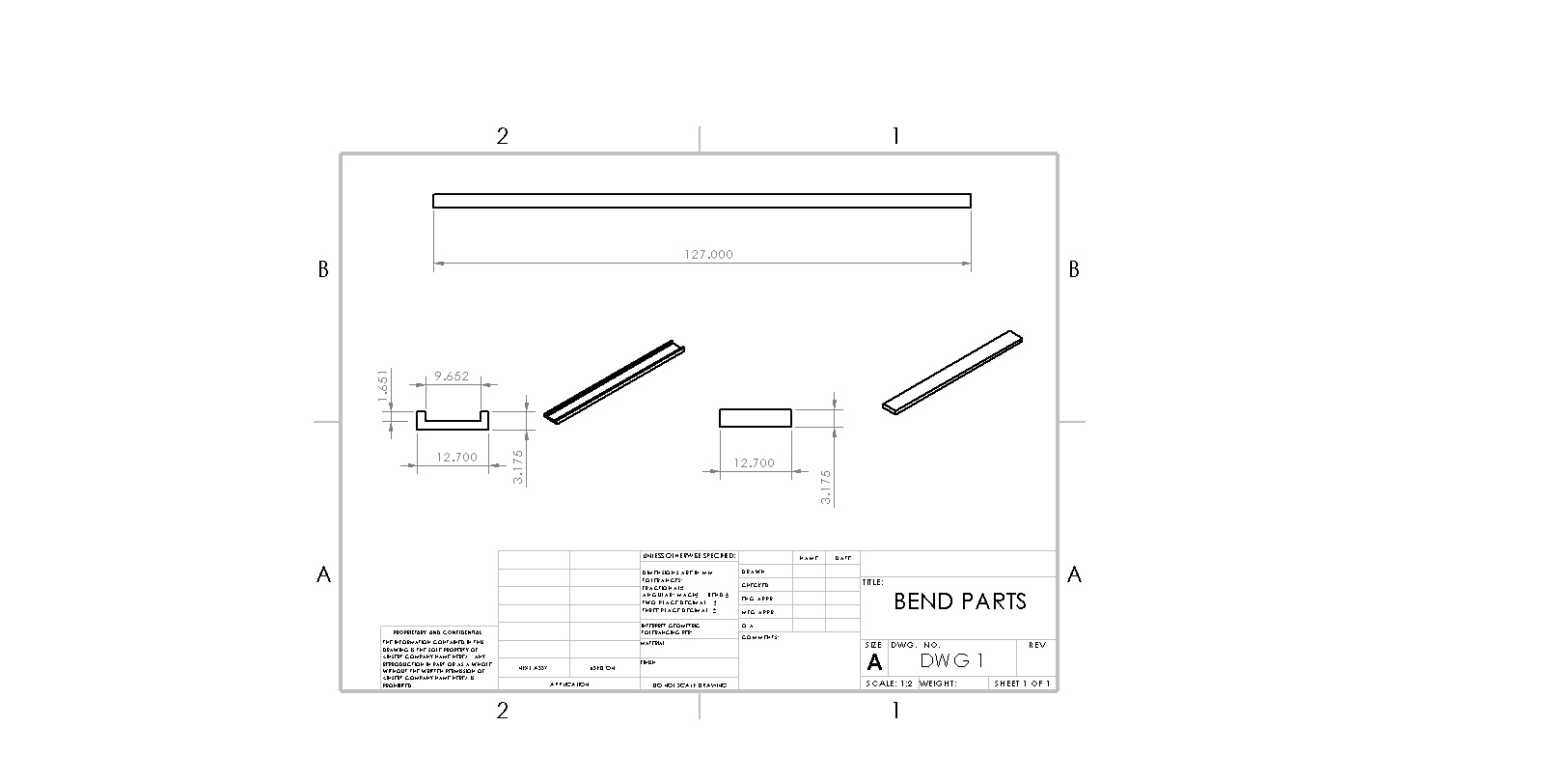

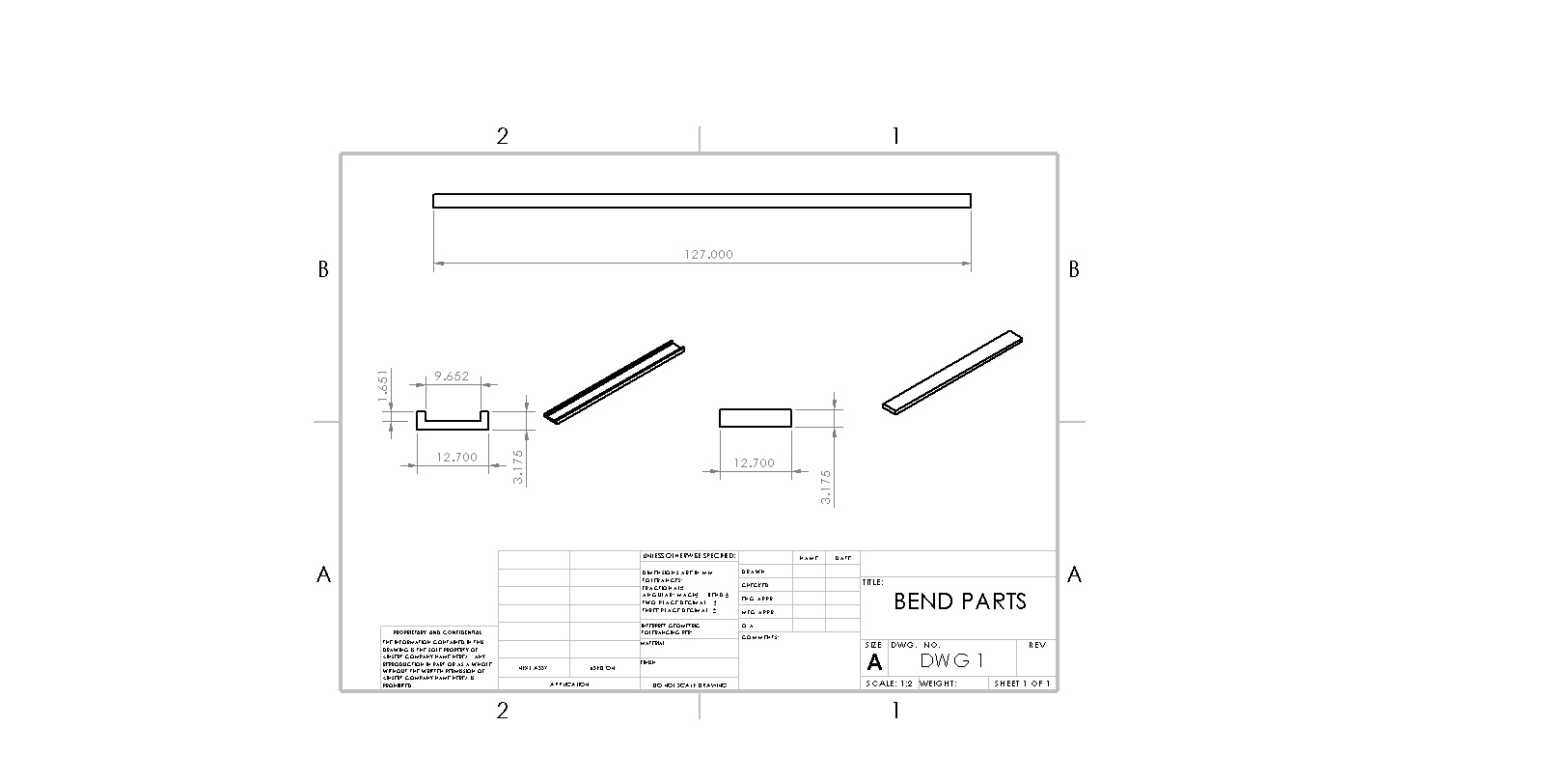

I then designed each part on SolidWorks using the relevent ASTM standards I could find: 5 in long, 0.5 in wide, and 0.25 in tall.

After designing and approval from instructor, the parts were printed. Due to time constraints, 3 samples of each treatment were printed.

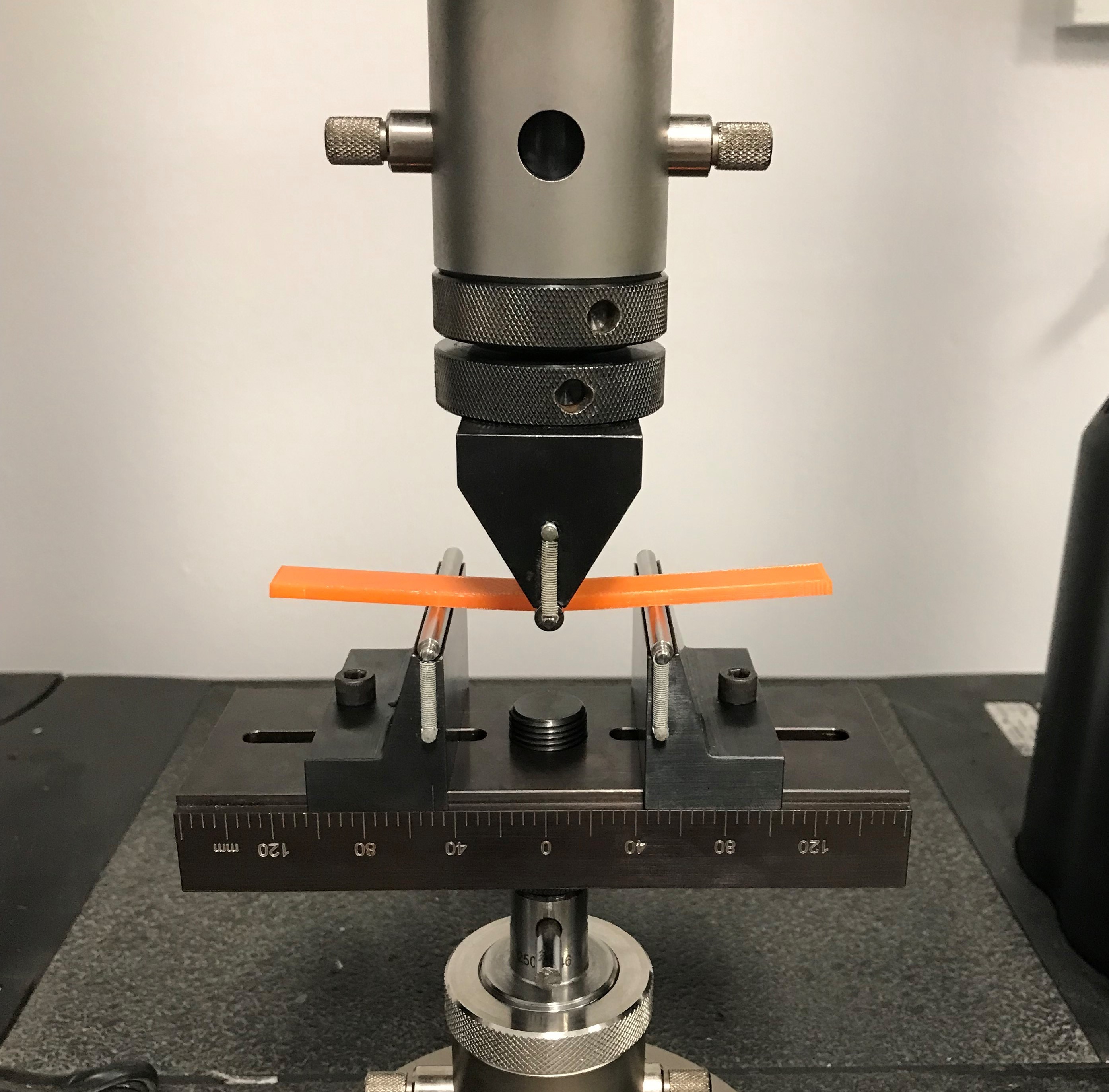

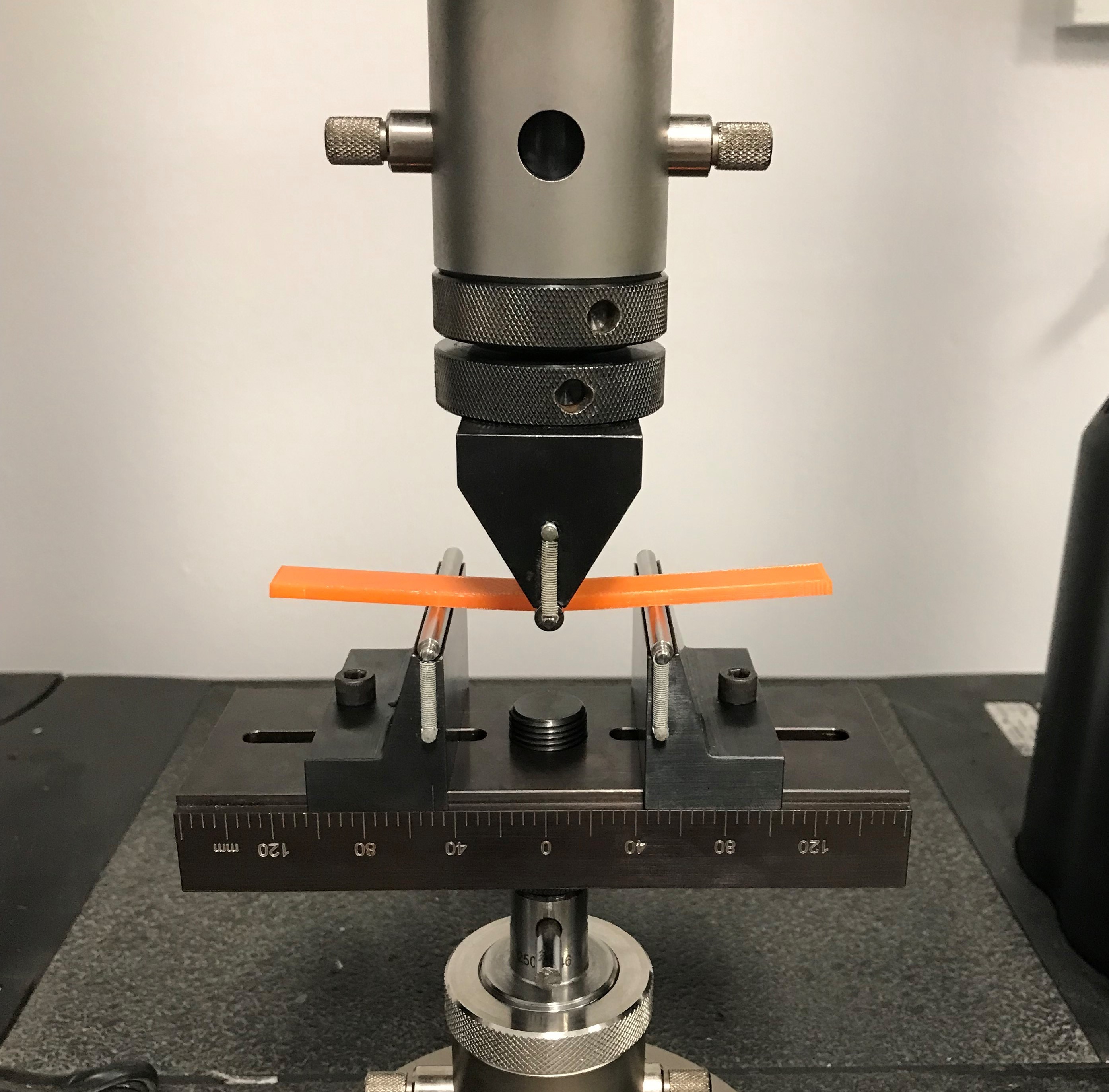

Using the school’s lab and 3-Point bend tester, each sample was placed under force at 1 N-per-second and broken.

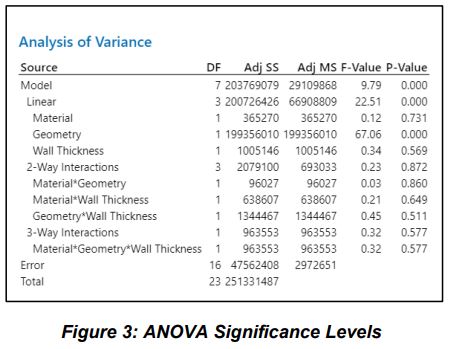

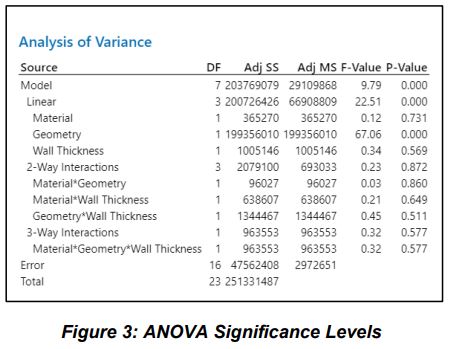

Data was kept on excel and exported to MiniTab statistical software for analysis. After analysing treatments using ANOVA methods, the resulting data was produced:

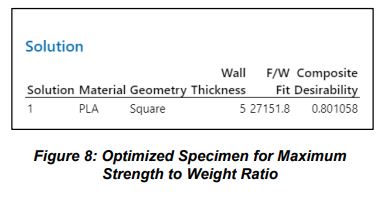

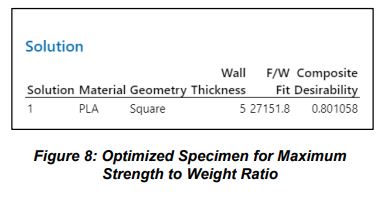

Perfomring optimization on the data, the best result is a combination of PLA-Square-5, which was contrary to the supposed ABS-channel at the start for best treatment.

If you want to see the full REPORT